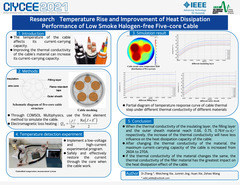

Research on Temperature Rise and Improvement of Heat Dissipation Performance of Low Smoke Halogen-free Five-core Cable

ID:165

Submission ID:147 View Protection:ATTENDEE

Updated Time:2021-12-03 10:44:12 Hits:797

Poster Presentation

Start Time:2021-12-17 15:05 (Asia/Shanghai)

Duration:5min

Session:[Z] Poster Session » [Z4] Poster Session 4: High voltage and insulation technology

Video

No Permission

Presentation File

Tips: The file permissions under this presentation are only for participants. You have not logged in yet and cannot view it temporarily.

Abstract

The current-carrying capacity of low-smoke halogen-free cables is affected by the temperature of the cable, and its heat dissipation performance restricts the current-carrying capacity. The temperature rise curve can reflect the heat dissipation performance of the cable. A model of a five-core cable is established, finite element simulation is performed on it, and its temperature rise curve is obtained. And designed a five-core cable temperature rise experiment, and measured the temperature rise curve of the long-term withstand temperature of the cable up to 90°C. Finally, the finite element simulation is used to study the influence of the thermal conductivity of the insulating layer, the filling layer and the outer sheath material on the temperature rise curve of the cable, and the influence of the change of the material thermal conductivity on the maximum current-carrying capacity of the cable. The results show that when the thermal conductivity of the insulating layer, the filling layer and the outer sheath material reach 0.66, 0.75, 0.76W·(m·K)-1, respectively, the change of the heat dissipation performance of the cable is no longer sensitive to the increase of the thermal conductivity. After changing the thermal conductivity of the material, the maximum current carrying capacity of the cable is increased from 260A to 270A. If the thermal conductivity of the material changes the same, the thermal conductivity of the filling layer material has the greatest influence on heat dissipation effect of the cable, and the influence of the thermal conductivity on the heat dissipation performance is marginal. Therefore, referring to the simulation results, a material with high thermal conductivity can be selected as the filling layer to improve the maximum current-carrying capacity of the cable.

Keywords

five-core cable,finite element,temperature rise curve,thermal conductivity

Speaker

Comment submit